Updated on August 13, 2025 11:00:34 AM

The IIP Certificate for Packaging is an official certification issued by the Indian Institute of Packaging (IIP) to ensure that packaging materials meet prescribed safety and quality standards. For businesses that store and ship perishable, hazardous, or export goods, it is especially crucial. This certification confirms that the packaging is strong, impervious to leaks, and able to safeguard the contents in a variety of handling and environmental scenarios.

Packaging containers such as boxes, drums, barrels, jerricans, and other materials are subjected to a battery of stringent performance and compatibility tests by the IIP. Depending on the type of product being packed, these tests include vibration, pressure, stack, and drop tests. Passing these tests certifies packaging as meeting national and international standards, including those established by the BIS and the UN.

An IIP Certificate is frequently required for companies engaged in exporting, particularly of regulated or hazardous goods, in order to comply with DGFT, Customs, and International Shipping Regulations. In addition to guaranteeing the safe transportation of goods, it also raises the brand's reputation in international marketplaces.

Export shipments are frequently required to adhere to packaging specifications established by international freight carriers or importing nations. Thus, this certification acts as a tool for quality control, facilitating efficient logistics and adherence to safety and environmental standards.

To put it briefly, whether the products are being shipped domestically or abroad, the IIP Certificate for Packaging assists businesses in ensuring product safety, legal compliance, and efficient logistics.

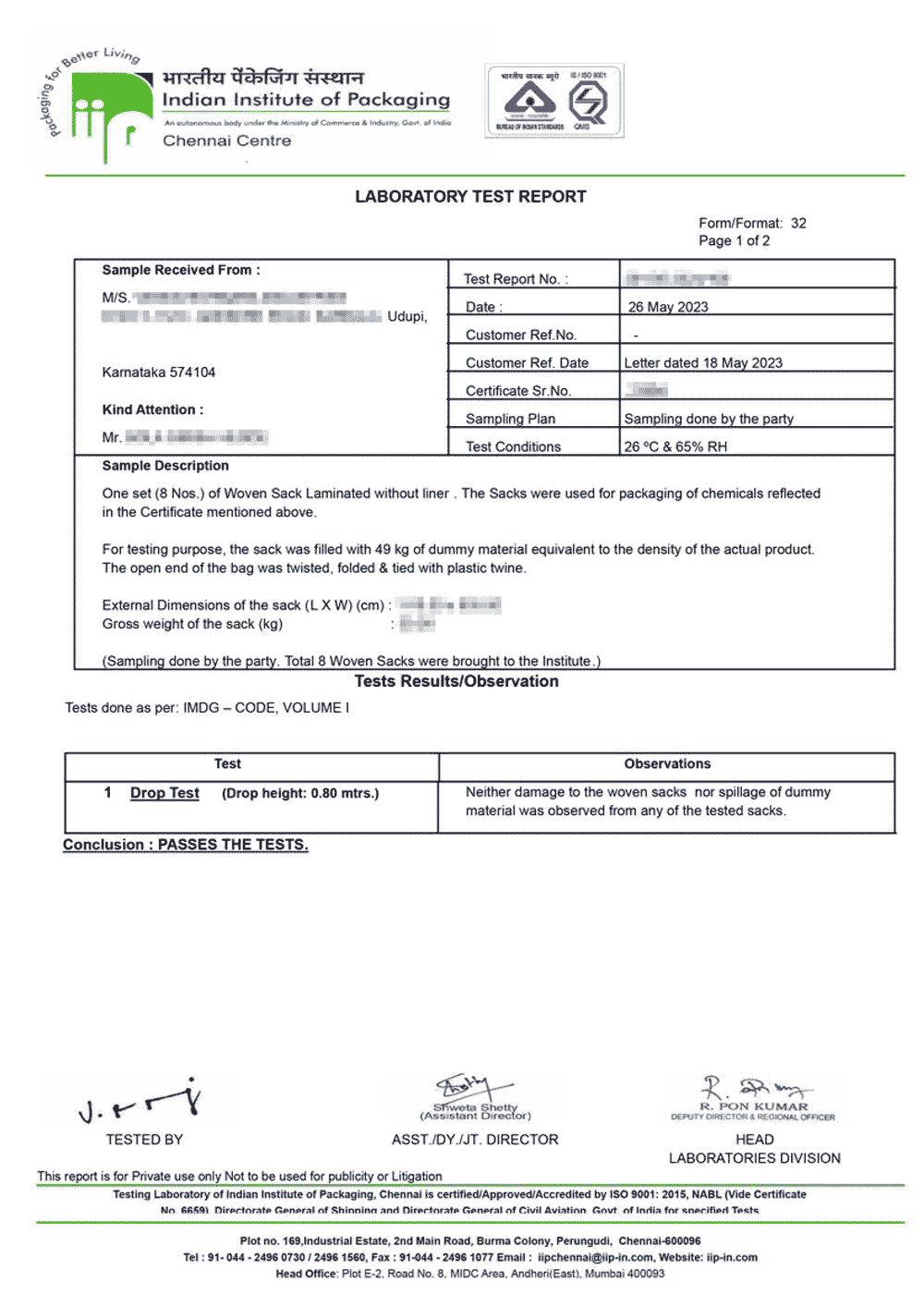

IIP Certificate Sample

Table of Content

The IIP Certificate for Packaging is issued by the Indian Institute of Packaging (IIP) and is essential for companies involved in the transportation of hazardous goods. This certificate confirms that your packaging materials meet the safety standards required for handling and shipping dangerous goods — both within India and internationally.

It applies to substances under hazard Classes 1 to 9 (like chemicals, flammable liquids, corrosives, etc.) and ensures your packaging has passed all necessary tests — such as drop, leakproof, stack, and pressure tests. These tests help guarantee that your packaging won’t fail during transit.

Having an IIP certificate not only supports safe handling and international shipping but also helps with customs clearance and regulatory compliance. If you’re exporting hazardous goods, this certification is a must-have for your business.

Here are the benefits of obtaining an IIP certificate for packaging:

The IIP certificate is not only the certificate brought for the hazardous goods, but it also has the ability to reduce accidents. The packaging material undergoes rigorous testing to ensure that it can withstand the rigorous demands of transportation, including vibration, stacking, drops, and extreme temperatures.

The IIP certificate helps hazardous goods flourish in the international market. This can open up new markets and business opportunities.

Most countries, like India, use IIP certificates for the transportation of hazardous goods. This is due to the use of UN approved packaging for transportation to avoid delays, regulations, and potential fines at customs.

The UN certification for hazardous goods allows a brand to facilitate safety and responsible handling, thereby enhancing the brand image of the hazardous goods.

Below is the complete checklist of documents required to obtain your IIP UN Mark Certification, ensuring compliance with UN packaging standards.

The IIP Packaging Certification is essential for packaging materials used in the transportation of hazardous goods, ensuring compliance with international safety standards. Below is a simplified step-by-step guide to help you navigate the process of obtaining your UN Mark Certificate from the Indian Institute of Packaging (IIP):

To ensure safe international transport of hazardous materials, packaging used must comply with UN regulations. The Indian Institute of Packaging (IIP) provides Packaging Certification for various packaging types. Below is a structured summary of government certification fees based on packaging material type:

| Packaging Material | Certification Fee (₹) |

|---|---|

| Fiberboard Drum, CFB Boxes (Corrugated Fiber Board), Paper Bags | ₹18,500 |

| Plastic Bags | ₹19,000 |

| Metal & Steel Drum / Jerrican | ₹19,500 |

| Woven Bags | ₹20,000 |

| Plastic Drum / Jerrican | ₹23,000 |

| CFB Boxes with Plastic Container | ₹24,500 |

| Composite Drums | ₹26,000 |

| FIBC Bags, IBC | ₹27,500 |

| Wooden / Plywood Boxes | ₹17,000 |

Note: Our Professional Service Fee: ₹25,000 (includes application filing, documentation, liaison with IIP, and end-to-end support).

Here are the types of packaging offered under the IIP certificate according to the proposed material intended to be transported:

The metal drums and barrels are both removable and non-removable head types (codes 1A1 & 1A2) for transporting a wide range of liquids, solids, and gases that are hazardous in nature. These types of metal drums and barrels have enough potential to withstand external pressure.

The plastic drums and barrels are both removable and non-removable head types (codes 1H1 & 1H2). These drums and barrels have the ability to withstand dangerous chemicals, however, they do possess certain limitations on the chemicals they may contain.

These drums (code 1G) are made from compressed cardboard and are a good option for less hazardous solids and powders.

Plastic jerricans are essentially heavy-duty plastic containers (code 3H1) typically used for transporting only liquids.

These are strong and secure options for packaging a variety of hazardous materials, especially those that require extra protection during transport.

These standard cardboard boxes (code 4G) are suitable for less hazardous solids when used in conjunction with proper inner packaging materials.

These wooden sack bags (code 5H3) are strong, flexible bags typically made from materials like jute or polypropylene and are used for packaging granular hazardous materials.

These combinations of plastic and steel composite drums and barrels (code 6HA1) combine the strength of steel with the corrosion resistance of plastic, making them a good option for specific hazardous materials.

These are flexible intermediate bulk containers or woven jumbo bags (code 13H3) used for transporting hazardous granules and powder in bulk quantities.

Here are the tests under UN regulations for the package material:

Conclusion

After providing suitable packaging for hazardous goods for the safe transportation of the dangerous cargo among UN countries, by obtaining UN mark certification, the position of the organisation can have the potential to gain market value. Getting certified for IIP isn't just about following the rules for packaging. It also makes good business sense. By having a system in place, you can train your employees better, which keeps your company growing and ahead of the competition in the long run.

At Professional Utilities, we leverage our industry knowledge and expertise to help businesses navigate complex regulations, minimize risks, and optimize operations for maximum efficiency and profitability.

"Explore how Professional Utilities have helped businesses reach new heights as their trusted partner."

It was a great experience working with Professional Utilities. They have provided the smoothly. It shows the amount of confidence they are having in their field of work.

Atish Singh

It was professional and friendly experience quick response and remarkable assistance. I loved PU service for section 8 company registration for our Vidyadhare Foundation.

Ravi Kumar

I needed a material safety data sheet for my product and they got it delivered in just 3 days. I am very happy with their professional and timely service. Trust me you can count on them.

Ananya Sharma

Great & helpful support by everyone. I got response & support whenever I called to your system. Heartly thanx for Great & Super Service. Have a Great & Bright future of team & your company.

Prashant Agawekar

Thank you so much Professional Utilities team for their wonderful help. I really appreciate your efforts in getting start business. Pvt Ltd company registration was smooth yet quick.

Abhishek Kumar

I applied for Drug licence and company registration and their follow-up for work and regular updates helped me a lot. They are happily available for any kind of business consultancy.

Vidushi Saini

Great experience went to get my ITR done, process was quite convenient and fast. Had a few queries, am happy about the fact those people explained me all things I wanted to know.

Taniya Garyali

Great services provided by Professional Utilities. They are best in this industry and the best part is their prices are so affordable. Kudos to you. Now you guys are my full-time consultant.

Aftab Alam

You can get your IIP certificate with the frequent assistance of professionals. This typically involves submitting samples of your packaging design for rigorous testing to ensure it meets UN standards.

Any manufacturer or exporter who needs to transport dangerous goods

by sea, air, or road requires an IIP certificate for their packaging.

Following are the benefits of using the IIP certified packaging:

You may need the following marking on packaging with an IIP certificate:

Speak Directly to our Expert Today

Reliable

Affordable

Assured