Updated on January 30, 2026 07:28:33 AM

The Make in India program has improved the electronics sector of the nation and led it into a hub of innovation, manufacturing, and self-reliance. Due to higher demand for smartphones, consumer electronics, and semiconductors, India has the potential to emerge as a global electronics manufacturing hub. Under the Make in India program there are various policies such as the Production Linked Incentive (PLI) Scheme and Electronics Manufacturing Clusters (EMC) that the government has implemented to boost the businesses. The Make in India initiative helps decrease import reliance, generates employment opportunities, increases exports, and encourages technological development of the electronics sector. Understand how the Make in India scheme is going to revolutionize the electronics manufacturing sector in India with Professional Utilities.

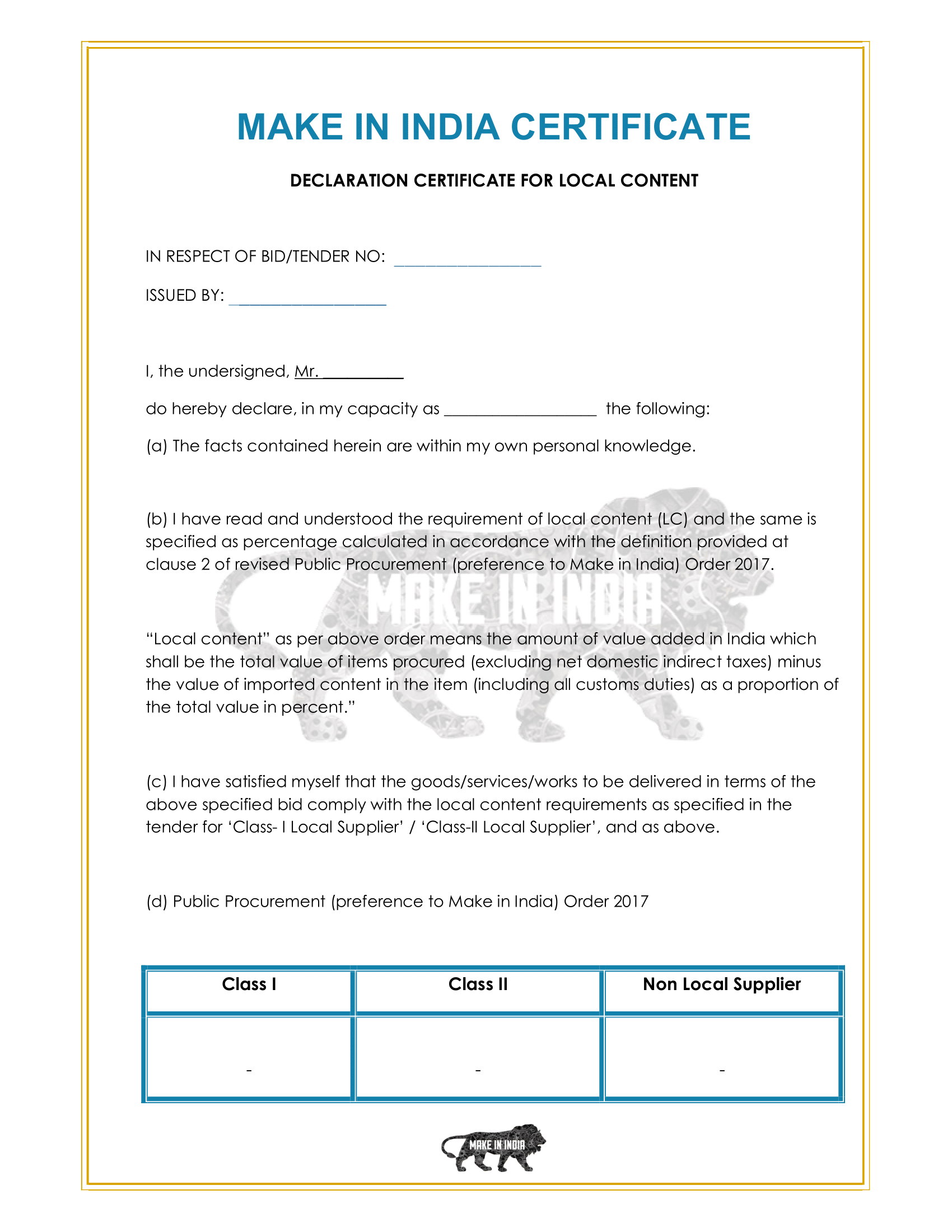

Make in India Certificate [Sample]

Table of Content

The Make in India initiative was launched in September 2014 and it seeks to make India one of the world’s manufacturing destinations. The Make in India aims to improve and develop the electronics industry further as it is crucial for economic development, job creation, and technology advancement. Make in India Scheme assists in creating employment, boosting manufacturing, which reduces import dependence and promotes investments helping India to gain better positioning in the global marketplace. The following article focuses on the role of the Make in India initiative in inspiring industrial change for the electronics industry of self-sufficiency, export drive and laying down the foundation for the realization of India’s potential as a global electronics hub.

The government of India has identified electronics manufacturing as one of the focus sectors under its Make in India program and It provides the following benefits to the businesses in electronics industry:

The professional fee for preparing a CA-certified MII certificate on an urgent basis is ₹9,999, and the issuance of regular certificate costs around ₹7,499.

| Particulars | Fees |

|---|---|

| On urgent basis | ₹ 9,999/- per certificate |

| On regular basis | ₹ 7,499/- per certificate |

Note: The aforementioned Fees is exclusive of GST.

The government has implemented various schemes to support electronics manufacturing under Make in India:

Eligible companies receive incentives for incremental sales in focus areas of the manufacturing industry which are mobile phones, semiconductors and consumer electronics.

Provides required and suitable structures for manufacturing plants all over the world and promotes industrial parks that deal with electronics.

Provides financial incentives for manufacturing of strategic electronics components.

Focuses on increasing digital connectivity and infrastructure, and increasing demand for electronics.

To boost local industries and cut down on imports, the Department for Promotion of Industry and Internal Trade (DPIIT) amended the Public Procurement (Preference to Make in India), PPP-MII, on June 4, 2020. The PPP-MII order classifies local suppliers into categories according to the local content in the goods, services, or works that they produce. The Make in India classifications are as follows:

The Make in India initiative scheme incentivizes domestic suppliers to enhance local content in their offerings and contributes to the growth of India’s manufacturing ecosystem.

While Make in India program has driven growth in the electronics sector, significant challenges remain and addressing these issues is crucial for fully realizing the potential of Make in India for electronic products:

Conclusion

The Make in India initiative has drastically improved the sectors of electronics manufacturing paving way for innovation and advancing manufacturing capabilities. Through lowering dependence on imports, the Make in India scheme encourages exports and employment and provides a solid base for making India an electronics hub. Policies under the Make in India program include the PLI Scheme, EMC Scheme, SPECS and more are integral to helping local industries and incorporating new technologies. Nevertheless, issues such as import dependency, underdeveloped infrastructure, skill development of human resources, and competition from the global players are a setback. Continued and determined efforts needed in Make in India can take the electronics industries to higher levels, for building a robust and sustainable manufacturing ecosystem.

Professional Utilities simplify registrations, licenses, and compliances for your business. With experienced guidance and nationwide support, we help you complete every requirement efficiently and effectively.

"Explore how Professional Utilities have helped businesses reach new heights as their trusted partner."

It was a great experience working with Professional Utilities. They have provided the smoothly. It shows the amount of confidence they are having in their field of work.

Atish Singh

It was professional and friendly experience quick response and remarkable assistance. I loved PU service for section 8 company registration for our Vidyadhare Foundation.

Ravi Kumar

I needed a material safety data sheet for my product and they got it delivered in just 3 days. I am very happy with their professional and timely service. Trust me you can count on them.

Ananya Sharma

Great & helpful support by everyone. I got response & support whenever I called to your system. Heartly thanx for Great & Super Service. Have a Great & Bright future of team & your company.

Prashant Agawekar

Thank you so much Professional Utilities team for their wonderful help. I really appreciate your efforts in getting start business. Pvt Ltd company registration was smooth yet quick.

Abhishek Kumar

I applied for Drug licence and company registration and their follow-up for work and regular updates helped me a lot. They are happily available for any kind of business consultancy.

Vidushi Saini

Great experience went to get my ITR done, process was quite convenient and fast. Had a few queries, am happy about the fact those people explained me all things I wanted to know.

Taniya Garyali

Great services provided by Professional Utilities. They are best in this industry and the best part is their prices are so affordable. Kudos to you. Now you guys are my full-time consultant.

Aftab Alam

Frequently Asked Questions

The Make in India aims to develop the country as a manufacturing powerhouse across sectors such as electronics and it fosters the growth of domestic industries, reduces import bills, increases employment opportunities and technological advancement.

Make in India is beneficial to the electronics industry as it cuts on importation, increases on exportation, creates employment and encourages innovation and assists in making India a electronics manufacturing hub.

The PPP-MII order classifies suppliers into three categories based on local content:

Class I and class II suppliers are the only ones allowed for bidding for procurement with a value not exceeding ₹200 crore.

The challenges include high import dependency where some crucial raw materials such as semiconductors are imported, low infrastructure, skillful human resource requirements, and intense competition from experienced nations such as China and Vietnam.

Speak Directly to our Expert Today

Reliable

Affordable

Assured

Make in India Initiative Across Key Sectors