The MSDS certificate for sodium sulfate is an important document that contains detailed information on the safe handling, storage, transportation, and disposal of this common chemical compound. Sodium sulfate is a white crystalline solid that is widely used in detergents, glass production, textiles, and paper making. Although it is non-toxic, unsafe handling can cause respiratory irritation, eye irritation, and environmental issues.

The MSDS certificate provides vital information, such as chemical properties, hazard identification, first aid procedures, fire fighting procedures, and spill containment requirements. It enforces adherence to OSHA (Occupational Safety and Health Administration), REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals), and GHS (Globally Harmonized System) requirements and assists industries in complying with safety standards and averting accidents at the workplace.

By keeping a current MSDS certificate for sodium sulfate, companies can stay compliant with regulations, reduce health hazards, and apply appropriate safety measures. This certification is necessary to advance safe industrial procedures, safeguard employees, and avoid environmental risks, rendering it an essential checklist item for firms dealing with sodium sulfate.

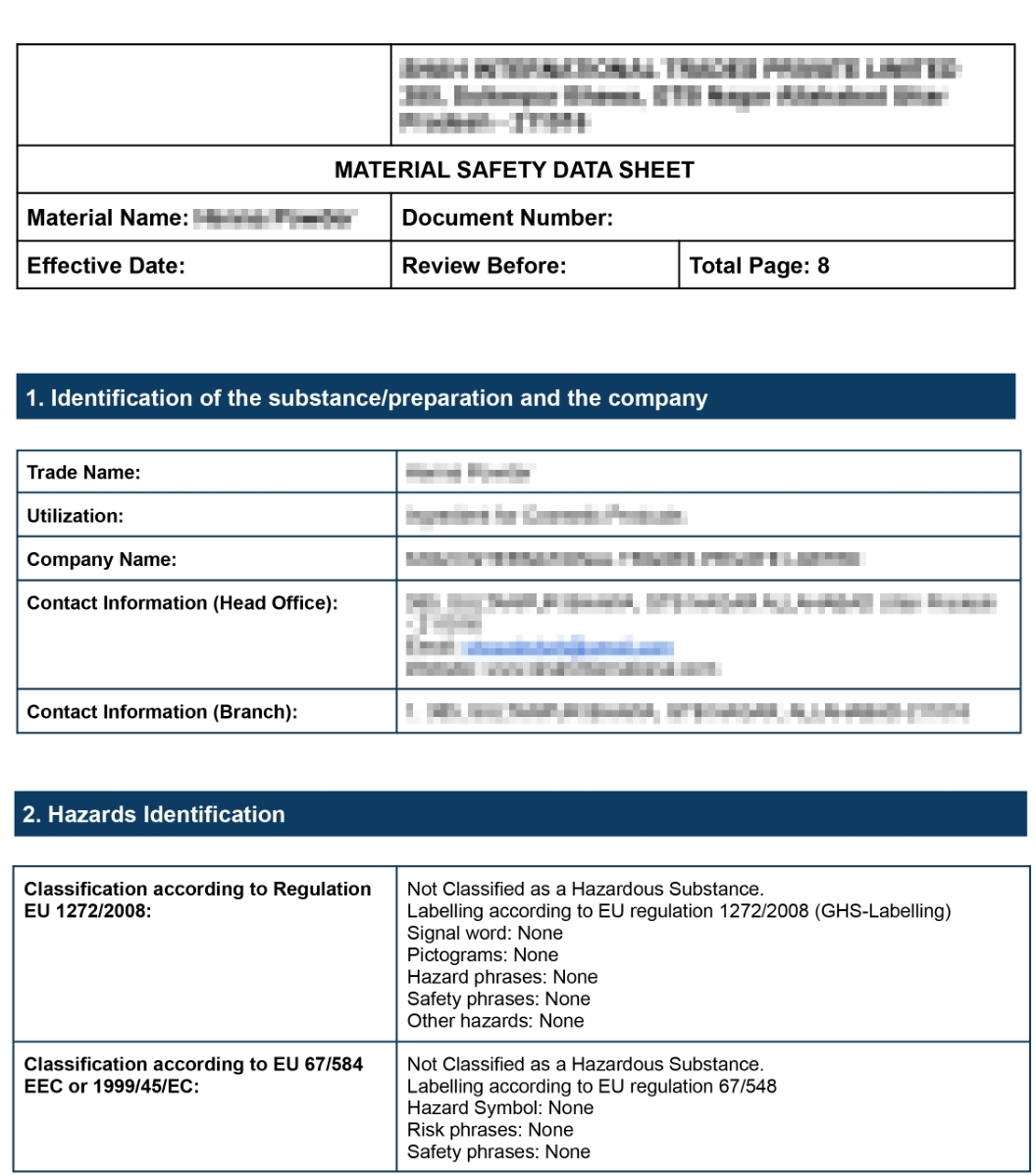

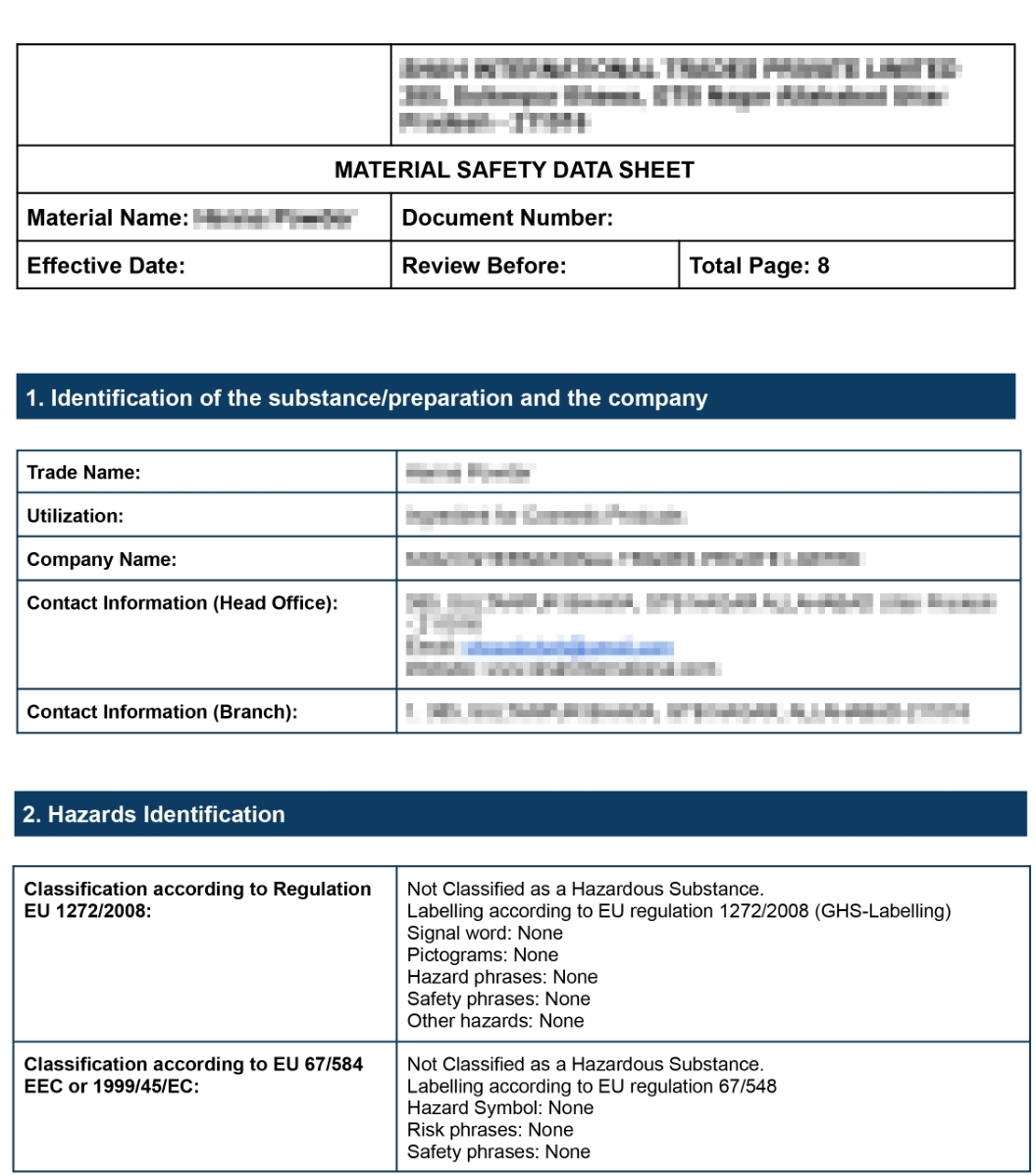

MSDS Certificate for Sodium Sulfate [Sample]

Table of Content

A Material Safety Data Sheet (MSDS) certificate is a formal document that contains comprehensive information regarding a chemical's properties, risks, safe handling practices, and emergency procedures. It is necessary for workplace safety and regulatory compliance when handling dangerous substances.

MSDS certificate contains important information like chemical composition, hazard classification, first aid measures, fire-fighting, safe storage conditions, handling procedures, and disposal practices. It provides workers, manufacturers, and industries with information on potential hazards and helps them take necessary safety precautions.

Government regulatory bodies like OSHA (Occupational Safety and Health Administration), GHS (Globally Harmonized System), and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) mandate that companies have a current MSDS certificate to be in line with safety guidelines.

MSDS certificate for sodium sulfate is very important in order to ensure safe storage, handling, and transport of this industrially used chemical. Although sodium sulfate is of low risk, it may result in respiratory irritation, eye irritation, and environmental hazards if not properly handled.

Obtaining a Material Safety Data Sheet (MSDS) certificate for NaOH requires submitting specific documents to regulatory authorities or certification agencies.

| Document Name | Description |

|---|---|

| Product Details | Information on Sodium Sulfate’s chemical composition, purity, and concentration. |

| Manufacturer’s Details | Name, address, and contact details of the manufacturer or supplier. |

| Chemical Safety Data | Information on toxicity, reactivity, and health hazards associated with Sodium Sulfate. |

| Handling & Storage Guidelines | Safe handling procedures, recommended PPE, storage conditions, and transportation guidelines. |

| Hazard Identification Report | Classification under GHS (Globally Harmonized System) and other regulatory standards. |

| First Aid & Fire Safety Measures | Emergency response procedures, including first aid, spill control, and fire-fighting instructions. |

| Regulatory Compliance Certificates | Approvals or compliance documents from OSHA, REACH, or other regulatory authorities. |

| Test Reports | Laboratory analysis confirming Sodium Sulfate’s composition and compliance with safety standards. |

MSDS (Material Safety Data Sheet) Certificate for Sodium Sulfate requires a formal process to abide by international safety standards such as OSHA, GHS, and REACH.

For Sodium Sulfate, the cost of an MSDS/SDS certificate starts at Rs 4,499 for one certificate and Rs 8,999 for two. You can get Multiple MSDS certificates at discounted prices.

| No of MSDS Certificate | Fees For MSDS Certificate (₹) |

|---|---|

| 1 MSDS Certificate | ₹4,499 |

| 2 MSDS Certificate | ₹8,999 |

| Multiple Certificates | 3Get Pricing by Contacting Us |

Note: The aforementioned fee is exclusive of GST

The MSDS certificate of Sodium Sulfate usually lasts for 3 to 5 years, depending on regulatory requirements and industry standards. However, it can be invalidated if there are new safety regulations, changes in chemical composition, or alterations in the manufacturer or supplier.

Regulatory bodies might call for a revised MSDS in case of new hazards being discovered or reclassification criteria being updated. Moreover, certain firms or clients might insist on periodic updates for regulatory compliance and safety guarantee. In order to remain compliant, companies should update the MSDS certificate periodically based on the latest safety standards and industry regulations.

Conclusion

The sodium sulfate MSDS certificate is an important document that guarantees the safe handling, storage, and transportation of this very common industrial chemical. Although sodium sulfate is relatively low-risk, mishandling may cause respiratory irritation, eye irritation, and environmental issues.

By keeping an updated MSDS certificate, industries are able to adhere to OSHA, REACH, and GHS safety standards, minimizing workplace risks and guaranteeing legal compliance. The certificate gives critical instructions on first aid measures, fire protection, spill prevention, and disposal, assisting in safeguarding workers and the environment.

Why Professional Utilities?

Professional Utilities simplify registrations, licenses, and compliances for your business. With experienced guidance and nationwide support, we help you complete every requirement efficiently and effectively.

Complete Corporate Solutions

PAN India

Assistance

Free Expert

Guidance

Google-Verified

Team

Dedicated Support

Transparent Refund

Assurance

"Explore how Professional Utilities have helped businesses reach new heights as their trusted partner."

Testimonials

It was a great experience working with Professional Utilities. They have provided the smoothly. It shows the amount of confidence they are having in their field of work.

Atish Singh

It was professional and friendly experience quick response and remarkable assistance. I loved PU service for section 8 company registration for our Vidyadhare Foundation.

Ravi Kumar

I needed a material safety data sheet for my product and they got it delivered in just 3 days. I am very happy with their professional and timely service. Trust me you can count on them.

Ananya Sharma

Great & helpful support by everyone. I got response & support whenever I called to your system. Heartly thanx for Great & Super Service. Have a Great & Bright future of team & your company.

Prashant Agawekar

Thank you so much Professional Utilities team for their wonderful help. I really appreciate your efforts in getting start business. Pvt Ltd company registration was smooth yet quick.

Abhishek Kumar

I applied for Drug licence and company registration and their follow-up for work and regular updates helped me a lot. They are happily available for any kind of business consultancy.

Vidushi Saini

Great experience went to get my ITR done, process was quite convenient and fast. Had a few queries, am happy about the fact those people explained me all things I wanted to know.

Taniya Garyali

Great services provided by Professional Utilities. They are best in this industry and the best part is their prices are so affordable. Kudos to you. Now you guys are my full-time consultant.

Aftab Alam

Frequently Asked Questions (FAQs)

An MSDS certificate is necessary for safe handling, storage, and transportation as it gives safety guidelines, hazard information, and emergency procedures.

Sodium sulfate is not toxic but may lead to respiratory irritation, skin irritation, and environmental issues if handled improperly.

Manufacturers, suppliers, and industries that utilize sodium sulfate in detergents, glass manufacturing, textiles, and chemical processing need an MSDS certificate.

Store in a dry, cool, and well-ventilated place, away from moisture and incompatible materials to avoid degradation.

In case of contact with eyes or skin, flush with water. If inhaled, relocate to fresh air. Provide medical aid in case of continuing irritation.

An MSDS certificate is good for 3 to 5 years, depending on when conditions of regulations and formulation of a product change.

Yes, it is required for regulatory compliance and ensures safe transportation by providing hazard classification and handling guidelines.

No, an expired MSDS certificate must be updated to comply with the latest safety regulations and chemical standards.

MSDS Certificate in Other States

Related Articles